Sig P320 Review

Although I used to recommend the Sig P320, and it was my primary range/training sidearm for a few years, I don’t recommend nor use it anymore because I no longer trust it to be a safe nor reliable firearm.

The P320 has been well-documented to have serious issues – we will explore those here.

There are three main issues I have with the P320 are: the drop-safe issue, the uncommanded discharge issue, and, after researching details on the first two issues, I have since discovered reliability issues identified by the Army in their testing.

I will walk through each below.

Sig p320 9mm Specs

- Overall Length 8 inches

- Barrel Length 4.7 inches

- Width 1.25 inches

- Weight 28.3 ounces

- Capacity 17 rounds

- Caliber 9mm

Sig P320 History

The Sig p320 has had more than its share of news and controversy.

I’m going to do my best to walk through the ups and downs for the pistol and the company, however, first it is probably best to start with a summary timeline of events to be able to follow everything.

Sig p320 Timeline

January 2014 – SIG Sauer announced the p320 pistol at the 2014 SHOT show, the firearm industry’s annual trade show. The p320 was a striker-fired adaptation of Sig’s p250, a double-action-only hammer-fired pistol.

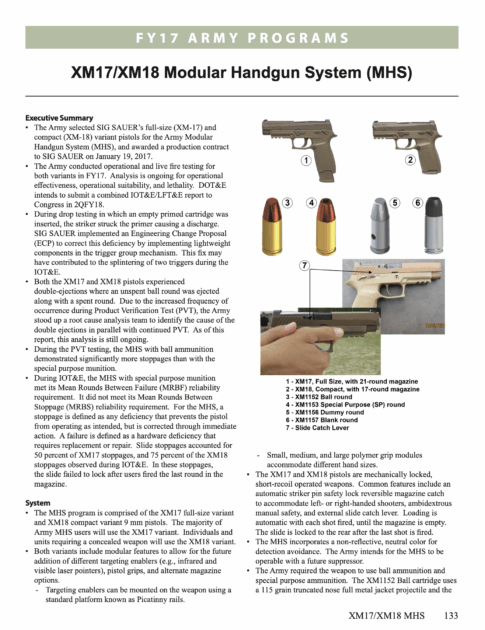

September 2015 – The United States Army, joined by the Air Force and Marine Corps, requested proposals for The XM17 Modular Handgun System (MHS) competition as a search for a new military sidearm/service-pistol.

February 2016 – Deadline for submissions to the MHS competition – testing and evaluation of submitted pistols begins.

August 2016 – The Army “down-selected” two handguns as finalists in the competition, Glock’s and Sig’s submissions (variants of the Glock Model 19 and Sig model p320, respectively). This started phase two of the competition where, among other things, the pistols were supposed to undergo destructive testing up to 35,000 rounds.

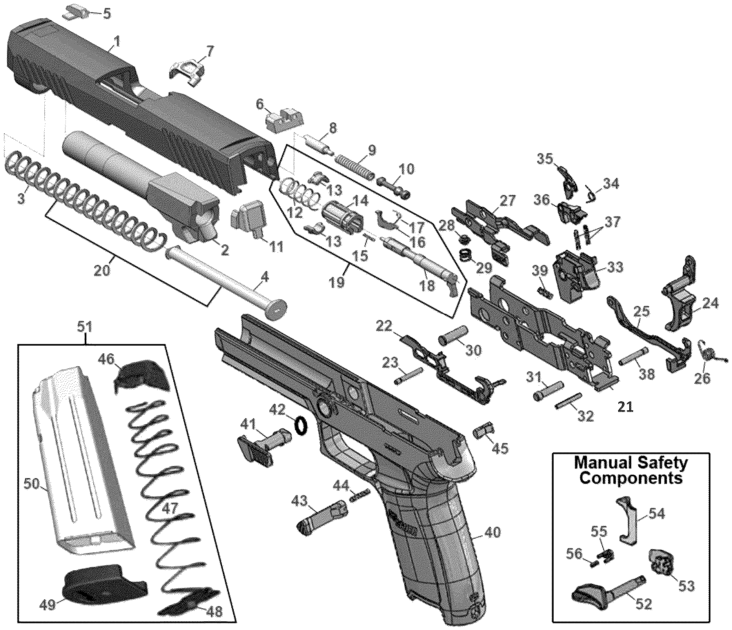

According to a FY17 summary of Army Programs for the Office of the Secretary of Defense (OSD), the Army discovered some issues with the Sig pistols – the XM17 (full-size variant of the p320) and the XM18 (compact-size variant of the p320). The document identified a drop-safety issue, which Sig fixed during testing, and reliability issues related to “double-ejections” and not meeting the requirements for rounds fired before failures or stoppages. The document does not identify nor discuss any issues that may have been found with the Glock pistol.

A discussion on the findings can be found below this timeline.

January 2017 – Sig was announced the winner of the MHS competition for their submission – a compact and full-size variant of their p320 pistol platform. Glock protested this announcement as “premature,” among other issues, because phase two had not been completed per the competition rules and was instead stopped at 12,500 rounds – well short of the planned 35,000 rounds and only half of the contract’s required service life of 25,000 rounds.

June 2017 – The U.S. Government Accountability Office (GAO) released the results of an investigation wherein it wrote that “Sig Sauer’s full-sized handgun had a higher stoppage rate than Glock’s handgun, and there may have been other problems with the weapon’s accuracy.”

August 2017 – Omaha Outdoors, after seeing rumors starting to circulate online about the Sig p320 firing when dropped, conducted their own tests and published a video on August 7th on the matter where they confirmed that the p320 would fire when dropped at a certain angle.

On August 8th, one day after the Omaha Outdoors article and video, Sig announced a “voluntary upgrade” program for the Sig p320. (Archived version of Sig Press Release)

March 2018 – All military branches adopt the Sig MHS pistol (military variant of the p320)

2018 – 2025 – In addition to drop-safety claims, numerous reports of “uncommanded discharges” (where a pistol fires without the trigger being pulled) start to be made. This includes reports from the military of multiple instances of soldiers being injured by p320 discharges and news articles like a Washington Post article from 2023 that claims that “more than 100 people allege that their P320 pistols discharged when they did not pull the trigger.” (It is important to note that the Washington Post compiled this information along with The Trace, an anti-gun organization. This article was not included to make a claim about what may or may not have happened to 100 people but rather to illustrate growing claims and scrutiny of the p320.)

It has also resulted in numerous lawsuits against Sig and even some law enforcement agencies, such as Immigration and Customs Enforcement (ICE), and law enforcement groups, such as the Washington State Criminal Justice Training Commission, banning the use of the p320.

Sig has continued to defend the p320 and insists that it is safe, it is impossible for a p320 to fire without the trigger being pulled, and that it meets and exceeds all safety requirements. Sig has even fought back, not just in defending its lawsuits, but also by suing the Washington State Criminal Justice Training Commission (WSCJTC) for banning its pistol. The WSCJT released a report detailing an uncommanded discharge during their training and highlighting six other uncommanded discharges on military installations.

The results of the lawsuits have been mixed. Sig has won some of the lawsuits against them for the p320, they have settled a few lawsuits, and they have also been found liable and negligent by a jury.

April 2023 – The Marine Corps investigated an issue and published a report about an incident involving an Uncommanded Discharge of a Marine’s Sig pistol. The Marine Corps, based on security camera footage, determined that the Marine did not mishandle the M18 pistol and that it was on “safe” and secure in the holster when it discharged.

August 2024 – After experiencing an uncommanded discharge with a Sig p320, the Michigan Sate Police ask the Federal Bureau of Investigation’s Ballistic research Facility to evaluate the pistol. The FBI’s report was not made public until July 2025.

March 2025 – Sig Sauer launches a website (p320truth.com) and social media campaign, with the caption “The P320. It ends today,” where they aggressively defend the p320 with statements like “The P320 cannot, under any circumstances, discharge without a trigger pull – that is a fact” and “The allegations against the P320 are nothing more than individuals seeking to profit or avoid personal responsibility.”

May 2025 – Sig seeks, and receives, legal immunity from the state of New Hampshire for lawsuits related to the Sig P320.

July 2025 – Airman Brayden Lovan was killed by a bullet fired by an alleged uncommanded discharge from his Sig M18 pistol. He allegedly removed his holster with the pistol secured inside, set the holster on his desk, and was killed after he was struck by a bullet from an ucommanded discharge (firing without a trigger pull) from the P320.

The Air Force immediately paused the p320 variant (M17 and M18) pistols from service.

Numerous training institutions, shooting ranges, police departments, and even the International Defense Pistol Association (IDPA), have now banned the Sig p320 pistol due to safety concerns.

Most recently, a federal jury determined that the p320 was “designed defectively” in a Cambridge police officer’s lawsuit.

August 2025 – Houston Police Department bans P320 after officer injured.

Air Force Announces arrest and manslaughter charges in connection with prior month’s shooting.

Issues found during Army testing

According to a FY17 summary of Army Programs for the Office of the Secretary of Defense (OSD), the issues with the Sig p320 variants during testing for the MHS program were described as:

- “During drop testing in which an empty primed cartridge was inserted, the striker struck the primer causing a discharge.” In other words, the Sig p320 variant would fire when dropped at a particular angle and height.

- “Both the XM17 and XM18 pistols experienced double‑ejections where an unspent ball round was ejected along with a spent round.”

- With ball ammunition, neither the XM17 (full-sized p320 variant) nor the XM18 (compact-sized p320 variant) passed the requirement for Mean Rounds Between Stoppages (MRBS) and the XM18 also didn’t meet the requirement for Mean Rounds Between Failures (MRBF).

For the drop-safety issue, “The Army directed SIG SAUER to develop an ECP [‘Engineering Change Proposal’ – changes to a product’s design] to correct this deficiency. SIG SAUER modified the trigger mechanism to eliminate this deficiency. Subsequent testing validated that this ECP corrected the deficiency and the pistol no longer fired when dropped.”

For the failure to meet functional requirements, the MHS competition reliability requirements were for the pistols to shoot 5,000 Mean Rounds Between Failure (MRBF) (an average of 5,000 rounds of ammunition fired before a part breaks) and 2,000 Mean Rounds Between Stoppage (MRBS) (an average of 2,000 rounds fired before a stoppage defined as “any deficiency that prevents the pistol from operating as intended, but is corrected through immediate action.”)

The 5,000 MRBF and 2,000 MRBS requirements applied to both “special purpose ammunition” and “ball ammunition.” The XM17 and XM18 passed the requirements with “special purpose ammunition,” however, there were issues with standard ball ammunition.

With ball ammunition, the Sig XM17 passed the 5,000 MRBF requirement with 6,944 MRBF demonstrated but fell short of the 2,000 MRBS requirement with only 343 MRBS demonstrated. This means that, on average, the XM17 experienced a stoppage every 343 rounds.

With ball ammunition, the Sig XM18 fell short of both the 5,000 MRBF requirement with 3,906 MRBF demonstrated and also the 2,000 MRBS requirement with only 196 MRBS demonstrated. This means that, on average, the XM18 failed after 3,906 rounds and experienced a stoppage every 196 rounds.

The government summary explains that the majority of the stoppages were due to the slide not locking to the rear after the last round of a magazine was fired. The Army attributed this to a high-grip when firing by the soldiers and determined that the issue could be resolved with training.

Although the failure of the slide to lock back accounted for the majority of stoppages, if the slide locking issue were ignored/eliminated, the pistols still would have not met the 2,000 MRBS requirement. Removing the slide-lock issue would increase the results to only 708 MRBS for the XM17 and 950 MRBS for the XM18 – both at less than half of the requirement.

Glock alleges that the Army chose to go with the Sig pistol and end the testing early because of cost. The Congressional Research Service put the unit cost for each MHS pistol at $180. At that price, it would cost the military $85.2 million for all 473,216 pistols – this leaves questions about the contract’s ceiling price of $580 million. It is not clear what the remaining $494.8 million is for nor where any of the money may have went.

P320 Drop Safe Issue

The first significant issue (or perceived issue) discovered by the public is the drop-safe issue.

Both the US Army and individuals in the civilian market have found that pistols based on the P320 platform can fire if dropped at a certain angle.

The issue exists when the pistol is dropped on the back of the slide and the trigger’s inertia carries the trigger rearward thereby firing the pistol. This issue with the P320 is due to the mass and spring tension of certain parts.

The Army brought this to Sig’s attention and Sig solved the issue by replacing certain parts with lighter-weight parts. Less mass in the newer replacement parts resulted in less inertial force.

Although Sig was aware of the problem and had a solution for the problem, Sig did not use these newer parts for the civilian commercial market until it became a public issue in August 2017 just after the Omaha Outdoors video. Until that video came out, they continued to use the older parts on civilian models of the pistol which would cause the p320 to fire when dropped at a certain angle.

After the Omaha Outdoors article and video, Sig stopped production of the p320 and stopped producing p320s with the older parts that would cause it to fire when dropped at a certain angle. Sig also started a voluntary upgrade program wherein anyone could send in their p320 to be upgraded so that it wouldn’t fire when dropped.

Sig insisted then, and continues to claim, that the P320 is the safest striker fired pistol on the market. However, if anyone was uncomfortable with their P320, Sig was happy to spend the time and money to upgrade the P320 free of charge.

One of Sig’s popular claims is that the P320 will not fire without the trigger being pulled. In this drop-safety issue, the claim is technically accurate because what caused the P320 to fire when dropped was the trigger moving to the rear under inertia.

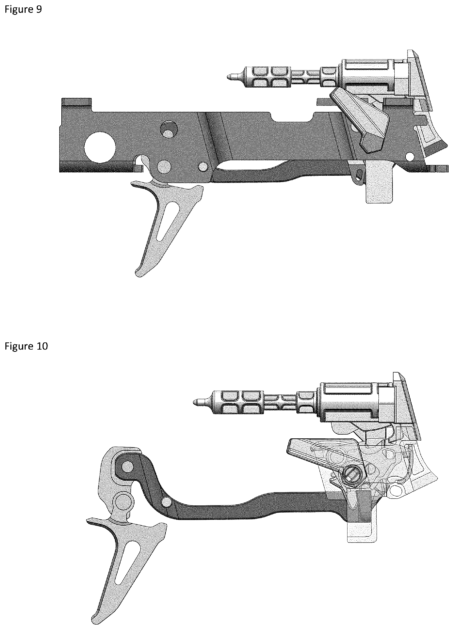

In addition to the new lighter parts, the issue could have been solved with a blade-style trigger safety that is common on almost every other striker fired pistol.

In fact, in an older brochure for the Sig P320, sig clearly contemplated a blade-style safety (see the top right trigger labeled “tabbed safety trigger” in this image below) but, for whatever reason, Sig chose not to use it.

At the time of this issue and the voluntary upgrade, Sig pointed out that the p320 passes every formal drop-safety test. Drop safety tests include certain heights and orientations and none of them called for passing a drop at a -30 degree angle.

In my opinion, once Sig was aware of this problem and they implemented a solution for the Army, they should have immediately fixed it in the civilian P320 as well.

After the voluntary upgrade and Sig started using the newer parts, the drop-safety issue stopped for all new and upgraded pistols (Of course, since it was not a recall, any of the 500,000 P320s since production started in 2014 that were not sent in for the voluntary upgrade still had the issue).

P320 Uncommanded Discharge Issue

Even after the voluntary upgrade and the fixing of the drop-safety issue for new or upgrade P320s, the P320 was still being blamed for firing without the trigger being pulled.

This can be seen in the many lawsuits and claims about it over the years.

In many cases, it appears that a foreign object made it’s way into the trigger guard, pulled the trigger, and thereby discharged the firearm. In these cases the pistol’s design was blamed, however, it performed as designed – to fire when the trigger is pulled.

There have also been claims that the P320 is firing after being “jostled” or by having the slide manipulated without the trigger being pulled.

The issue here seems to be that the P320 is a striker-fired pistol that is fully-charged when it is at rest. The best example to explain this is a pinball machine ball launcher. In a Glock pistol, the launcher is pulled back as the trigger is pulled and then it is released. In a Sig P320, however, the “launcher” (striker) is pulled all the way to the rear as its normal state and it simply released upon the trigger’s pull.

In the P320, the striker is held to the rear by a small notch in the sear (a component of the trigger assembly). When the trigger is pulled, the sear is lowered which releases the striker. If the striker is able to over-ride (or slip over) the small notch in the sear, then the striker can move forward on its own.

To prevent this from causing a discharge, the Sig P320, like most other modern pistols, has a safety mechanism in the slide that prevents the striker (or firing pin) from moving forward enough to strike a primer and fire a round. This safety mechanism is designed to move out of the way only when the trigger is pulled.

Although this should stop a round from firing if the striker slips off the sear, it is a mechanical device that can fail.

In some of the claims of uncommanded discharges, it appears as if the pistol’s slide can be manipulated enough to cause the striker to slip off the sear. If the safety mechanism in the slide is working, a round wont be fired. If it fails, a discharge will occur.

Upon seeing these issues, I grabbed one of my personal P320 pistols to investigate. It is important to note that the P320 I used to test (and included below in the video) is 100% stock and in the exact factory condition which it was sent to me directly from Sig.

I found that I could, occasionally, get the striker to release by simply manipulating my slide. I could get it to release more often if I moved the trigger approximately 1/8th of an inch to the rear (I’m estimating that the P320’s trigger has about 3/4th of an inch of pre-travel before it will fire) while also jostling the slide.

The most concerning condition I found, however, was during a “function check” of the pistol where I pulled the trigger to release the striker, held the trigger to the rear, and then re-charged the pistol by puling and releasing the slide. At this point, with the trigger still held to the rear, I can get the pistol to fire every time by simply moving the slide.

What I found is NOT the same as a P320 just “going off by itself in a holster.” However, it does show to me that there is an issue with the design wherein the tolerances allow a slide movement to release the firing mechanism.

This should not happen on any firearm.

It appears that it is at least possible for the P320 to fire after being jostled – especially if the internal safety mechanism in the slide is stuck or otherwise inoperable.

After continuing to test the pistol, I noticed more issues with it:

After publishing the above videos, Phil Strader, a Sig executive, reached out to me and said that he might know what’s going on because he had experienced something similar before. He suggested that I assembled the slide onto the frame without using the slide stop lever – I just held it in place while locking the takedown lever.

The Sig manual explains to use the slide stop lever and I did not follow the manual. Phil pointed out that the magazine should not be able to be inserted in this condition and he is correct – I can only insert a magazine if I lock the slide to the rear using the slide stop lever.

Please see this follow-on video I made to explain the issue and my thoughts. Although the condition is arguably not dangerous because a magazine should not be able to be inserted, it still makes me not trust the P320 system:

A former engineer for Sig has invented a fix for the P320’s firing mechanism. Brian McDonald has a patent for a replacement kit that proposes to fix the safety issues with the Sig P320. Currently, the design is owned by Angled Spade.

Sig’s Handling of the Issue

So far, Sig’s response has been to say that there’s nothing wrong with the P320. They continue to claim that it is 100% safe and it is the “most tested pistol in the world.”

Unfortunately, I have direct experience of the striker sliding over the sear for an uncommanded discharge condition, there are simply too many claims and injures attributed to the P320, and things like the Army’s MHS results draw serious concerns about bot only the P320 but also what Sig is telling us.

Sig has gone on the offensive and is suing organizations that have banned the P320 for safety concerns and recently sent out an email and statement asking people to report on ranges or training institutions that have banned the P320.

In my opinion, Sig needs to admit that the P320 is not safe, recall every single P320, and either fix the design or replace it with something else. If Sig does anything short of this, they risk more people being injured or killed, they risk long-term brand damage, they risk being sued by police departments and civilians, and they will lose our trust.

Recent Posts

January 19, 2026

January 12, 2026

January 10, 2026

January 10, 2026

I was contemplating a P365, right up until this week. Now I’m not … after reading this plus watching a video called “Gun Engineers Reveal True Cause Of The P320 Uncommanded Discharges” from TriggerSmart.

Seems like (a) the basic design cannot be trusted (so why would I trust the FCU in a P365 any more than in a P320?) and (b) the company’s leadership cannot be trusted

Yeah, I saw that video. It’s full of misinformation. First and foremost is the claim that the springs can wear out just by sitting in the gun. That is completly false. Spring steel does not wear out by sitting in a static position. Whether under full load, partial load or un-compressed. It makes no difference. Springs only wear out through cylical action. And even then, for a spring to loose it’s tension would take thousands of cycles. The standard spring would require upwards of 10,000 cycles before loosing tension and a high cycle rated spring would be somewhere between 25,000-50,000 cycles before loosing tension. If the owner was taking proper care and maintenance of the weapon, they would have changed those springs out long before they reached that point. Failure to do so would indicate gross neglegence on the owners part. And, even if the springs were to loose tension, you would most likely be plagued by light primer strikes long before they would ever be weak enough to cause a total failure. And lets be honest, how many shooters, even LEO and regular military will ever reach 10,000 rds with their side arm. Some shooters will, certainly. Competitors and very avid shooters. But most weapons owned by the average gun enthusiast will not see 10,000 rds through it’s entire life.

There are several other areas of mis information in that video as well. Sorry, but the conclusions simply do not seem credible.

I decided to give Ryan’s tests a go with the DH3.

Ryan States:

I found that I could, occasionally, get the striker to release by simply manipulating my slide. I could get it to release more often if I moved the trigger approximately 1/8th of an inch to the rear (I’m estimating that the P320’s trigger has about 3/4th of an inch of pre-travel before it will fire) while also jostling the slide.

The most concerning condition I found, however, was during a “function check” of the pistol where I pulled the trigger to release the striker, held the trigger to the rear, and then re-charged the pistol by puling and releasing the slide. At this point, with the trigger still held to the rear, I can get the pistol to fire every time by simply moving the slide.

I tried time and time again to duplicate this with my P320-XFive DH3 without success. Now, I know my DH3 pistol has all of the safety upgrades because I checked the serial number, called Sig, and performed the visual inspections.

Again, if you own a 320 and have any concerns, I would send it in for the free upgrade program and return it to service. I remain confident in the safety of the DH3, but I do not deny that there may be some design flaws in the earlier pistols as Ryan has determined.

This pistol was an “upgraded” pistol straight from Sig and in 100% factory condition. I have edited the article to add a third video explaining the issue – it appears that this condition exists if I assemble the pistol without using the slide lock lever.

I have an early P320 and, at first, did not like firing it. The slide moved up a lot as I pulled the trigger. A Wilson Combat grip module seemed to fix that and made it more comfortable to shoot. Then I joined a department with them, and we had many malfunctions. Failures to eject, failures to feed, etc. It was scary from a reliability standpoint. Deep cleaning reduced the malfunctions but they still were too frequent.

Troubling to me is the FBI report showing they shipped new guns with “dead triggers” caused by out-of-spec parts. That, along with a “manufacturing artifact” discovered shows something is wrong with QC. Then they get the NH legislature to protect them and, by their own admission, only the manufacturer from lawsuits not other parties involved in the use and distribution of the firearm. Police departments and stores will be own left responsible for the lawsuits.

I have an M18 with a safety which I’ve had no issues with. But until this situation is resolved I will stick with my P226 Navy (which I absolutely love) and my P365 Xmacro comp.

I contacted Sig regarding an issue with my P320. They requested that I return the firearm for inspection; however, I declined to incur such costs and have consequently decided not to purchase any additional products from Sig. The core concern is their refusal to address the problem adequately, which poses safety risks to myself and other customers. This issue first occurred during my initial visit to the shooting range and reoccurred subsequently. Upon cocking the firearm, the magazine dislodged unexpectedly, without any intervention on my part to disengage the safety mechanism. I have also observed other firearm owners reporting similar issues, including one individual who stated that the magazine fell out during firing. I plan to exchange this firearm in hopes of acquiring a more reliable alternative. I regret this purchase and am disappointed with Sig’s customer service and its handling of such concerns.

One of my pistols is the P320 X-carry. Of the compact high-cap pistols that I own, the 320 is by far the most used and carried. It’s natural pointability, relatively low center of gravity and excellent trigger make it a joy to shoot. I have over 2000 rds through it with enough holster use to polish the slide. It has not missed a beat in 2000 rds…here’s the caveat…the FCU has to be seated correctly. Also, some holsters do not work well with the P320’s short trigger pull. In my own expierience;

1) After looking over my Safariland 6390ALS, and studying the pistol/holster when removing and re-holstering the weapon, I noticed the 6390 has a ledge, or a corner right up at the top of the trigger well. If the weapon is tilted out a little too much during holstering, that corner has the ability to occasionally catch and even hold the trigger if the retention screw is set tight enough. With a short trigger pull, that could be a recipe for disaster. I heated up my 6390 and reshaped the trigger well so that it can not come in contact with the trigger. But that isn’t the weapon’s fault. That is a design characteristic of the holster. One weapon, hundreds or thousands of holsters. It isn’t the firearm manufactureres responsibility to make sure their weapon works reliably with every holster made. No, it’s the responsibility of the holster manufacturer to ensure safe function with the weapon.

2) Most importantly. The FCU must be seated properly. I noticed when I first started shooting the P320 that sometimes after inserting the FCU, the slide would be difficult to put back on. I might have taken 3 or 4 attempts before the slide would finally line up properly and slide over the FCU. And even then, the slide would not assemble smoothly. Or sometimes, I would get the weapon assembled and the slide would be riding extremely high in the back and unevenly on the frame. The slide would also have a lot of verticle and latteral play. Whenever that happened, I would imediately break the weapon down and re-assemble. I think this is a crucial piece of the puzzle. Since all the scuttlebutt has been flying around implying the 320 isn’t safe, I have been trying to figure out for myself what is happening. To make a very long story short, I can reproduce an AD when the FCU is not installed correctly. Conversely, as long as the FCU is seated correctly, I have found it virtually impossible to produce an AD without manipulating the trigger. Impossible.

But, this isn’t the weapons fault either. If a shooter is not paying attention and assembles his weapon incorrectly and that inadvertently results in an AD, that is not the weapons fault. That is operator error. BTW, I do not believe Sig has lost any lawsuits or made any settlements based on the P320 fireing uncommanded. So far, to my knowledge, Sig has either won the case, the case was dropped by the plantiff or the case is still in the system. The only settlements paid by Sig that I have been able to find were because of the Gen1 drop fire. Which was repaired in 2017 and a free upgrade offered. Sig has maintined that AD’s are operator error and so far they have been prevailing with that argument.

I have the p320 and was able to make it fire also by manipulating the slide and very tiny pull of the trigger. It is now a paper weight. Sig won’t admit to anything, I have the x10 which runs fine only with certain types of ammo. Magazines are total garbage, will only function with 180gr rnfp ammo. Hollow point won’t feed , gets hung up in magazine. Contacted Sig about this issue and they told me that they sell so many firearms that some bad magazines are not an issue to them, WTF ! From that moment I was done with Sig. I hope they go under

Great article. Ranger thorough.

You know, you buy a gun for several reasons and one of them is that it holds value. Sure there are guys out there that will still buy them knowing what’s going on, but I can’t count on a P320 to hold its value any more than hold its firing pin. That’s sad. This is the only gun buy back program I’d ever support—Sig buy back these guns..

Did you read Bruce Gray’s comments about the pistols a couple years ago? All the P320 he examined had either been modified or the ammunition was defective. His article mainly addressed the issue of the pistols “blowing up”. The issue with the XM17/18 and police reminds me of the issue of the Beretta 92F back in the ‘80s. Slides breaking off pistols, accidental discharges. Turned out to be the issued 9mm was designed for sub-machine guns. Beretta added the hump on the left rear frame so if the slide did fly off it wouldn’t hit the shooter in the face, at least that was the theory. The accidental discharges were a training issue, finger on the trigger when holstering or handling the firearm. The testing was interesting. The “testers” preferred the Sig P226 and HK P7M13. But of course these were the more expensive options . After leaving the Corps I went into law enforcement and was issued a revolver, then we transitioned to the 92F. Lots of ADs there too. And issues with holstering. The Safariland 280 holster (the best holster they ever made). had a strap that could fall inside the trigger guard if not holstered correctly. This issue was solved by having the strap fall forward away from the trigger guard. It made the holster even better. But by then it was too late. The Deputies/Officers who didn’t train forced the changes. Then of course there is the debate about is it safety or a decocker and how do you carry it – on or off?

In anything mass produced there will always be issues. I would imagine in the course of saving money the QC was cut to bear bones. I have a Legion X5 with no issues. One thing I always did question about the P320 /Legion is why the slide lifts up in the rear when the trigger is depressed/squeezed/pulled and then it drops down after the striker is released. So the next question? Will there be another upgrade, buy-back, trade -in or will the P320 become the Covair and Pinto of the pistol world.

Perhaps a more reliable variant of the 1911 would be better because no one ever had an issue with that platform. A double stack 1911!!

I have owned the P320 X-Five DH3 for a few years. The first thing I did was to confirm it had all of the safety upgrades, including the mechanical disconnector, which are offered through the P320 Voluntary Upgrade Program.

I have not had any issues with the pistol, and it’s incredibly accurate. If you have any concerns with your P320, send it in for the free upgraded components.

Is there a combination of user error and mechanical error with the P320? The likelihood is great but still requires further investigation by all parties.

Just use the gun with an empty chamber. I have never owned a Sig and never will but I never put a round in my semiauto pistols until I am going to fire them. Sig owners should trade them in for a S&W M&P. Problem solved.

Great write-up! I’ve got a P320 X-Five Legion and really like it, but I’m wondering—do the safety concerns about unintended discharges apply to the Legion model too?

Haven’t seen anything specific about it, so just curious if it’s affected the same way or not. Appreciate any insight!

Same

The only P320 I own is the X5 Legion. So far, I’ve been unable to duplicate the slide manipulation to cause the striker to release. I’ve even tried with the trigger pulled almost to the point of breaking. Does it have a different trigger/striker system than the regular P320’s, or is it just made to tighter tolerances, or did I just luck out and get a “good” one?

Anyway, very informative article. Keep up the great work! Thanks!!

I have a 320X5 and a 320 AXG with no issues or concerns. During covid I was at my local range shooting either CCI or Speer. One one shot, I pulled the trigger heard a hiss and then regular sounding bang. At the same time something hit me in the face. Looking at the 320x all looked fine. However I could not fire any subsequent shots. The RSO had a 320 Legion and fired shots from my mag, could not fire anything fusing his mag. Got home and thoroughly cleaned, nothing apparently wrong. Phoned Sig and explained what happened. The rep said to look at the extractor. Sure enough it was gone. He said the gin is designed to blow out the extractor if pressures exceed norms as a safety issue. He advised to send the gun back. They replaced the extractor and the barrel free of charge. They could have said it’s the ammo’ fault and detect me there for resolve. Sig has always provided excellent customer care and stood behind their products from my pov. Hopefully they will resolve this as well . It should be noted that 1911’s and non 4 series Staccatos will fire when dropped. Col Cooper’s advice: Don’t drop them!

I own several P320 and P365. Is there a problem with the P365 like the 320? Why not use the trigger system on the 365 and solve the problem. I have never had a single problem with the P320s, but get tired of all the problems with this system. Find a fix and get on with life.

Sig P320. I had mine for two years now with No issues whatsoever. I teach firearms training in the military. safe gun handling is stressed to the max. There have been no accidents of any kind.

Its not the gun, its the human factor that causes those mishaps.

It’s great to hear that you haven’t witnessed any mishaps, however, that doesn’t mean that the gun is fine. The drop safety issue has been well documented by both the military and civilian worlds, the reliability issue was well documented, and it now appears there’s a new uncommitted discharge issue.

I’ve owned a P320 Compact for about five years. I love the firearm, but have stopped using it outside of the range. I live near Sig and want to support this local business. I initially placed my trust in Sig and every time a report of an uncommanded discharge arose, I would review Sig Mechanics, Sig Guy, Sig Talk and other outlets I trust and it seemed to me that Sig was correct… there’s no mechanical explanation other than perhaps a catastrophic internal failure. That said, I’ve become fatigued by having to convince myself it’s safe each time a new report comes out. I no longer have the time to revisit and re-convince myself every few months. I understand all mechanisms can fail and given the number of P320s on the market, there will be a certain number that do… sometimes with life altering results. This is true regardless of manufacturer. I want to continue to trust Sig, but they need to do something because this issue has gone from a purely mechanical debate to one of perception, and as we know, perception is reality in this world. Sig would be wise to heed your advice, initiate a recall or replacement, and incur short-term pain for long-term sustainability. I wish them well.

interesting report Chris. good read. I have a P320, that went through Wilson Combat’s factory. it is my favorite handgun next to my Wilson Combat CQB 1911. it has functioned flawlessly with any ammo, no steel jacket ammo, and it it is scary accurate. Has your findings experienced issue with the Wilson P320?

Thank you for the article, timeline and insight into the DoD testing data (as well as the unaccounted for monies that the DoD allotted for testing.) The issues that Sig faces with functioning is actually separate from the PR issues. Posturing is one thing, but becoming aggressive and suing private and public institutions for banning that gun is an entirely different matter and one where they planted their best foot right in the middle of a pile. People in the gun and 2A community are no longer asking if the 320 will save their life but if it will take their life. Why take the chance? Sig has already offended most in the gun community by stating that it is a money grab by anti-gun leftists, when all that civilian 320 owners were asking for was assurances that their pistol wouldn’t accidentally discharge. Sig has not been forthcoming with a viable solution to their PR problem that they created themselves. All that they have done is create another word salad that said the same thing that they have said before but in a nicer way. As for the solution for the 320 issue of “uncommanded” discharges, why not try the FCG that has been patented by an ex-Sig engineer? It couldn’t possibly be any worse than what Sig has done to themselves already. AND it may solve the issue.