Barrel Rifling 101: Types, Twist Rates, and More

Barrel rifling is an important concept for shooters to fully understand and apply in their training. It affects the accuracy of your shots, as well as helps you to choose the right barrel based on the desired ammunition or ammunition weight.

By exploring what barrel rifling is, twist rates and more, you’ll be able to make better decisions and gain more confidence in your journey with safe and effective firearms training. To do this, we’ll help explain what rifling is, why it’s important and what things you should think about.

With that, let’s begin.

What is Rifling

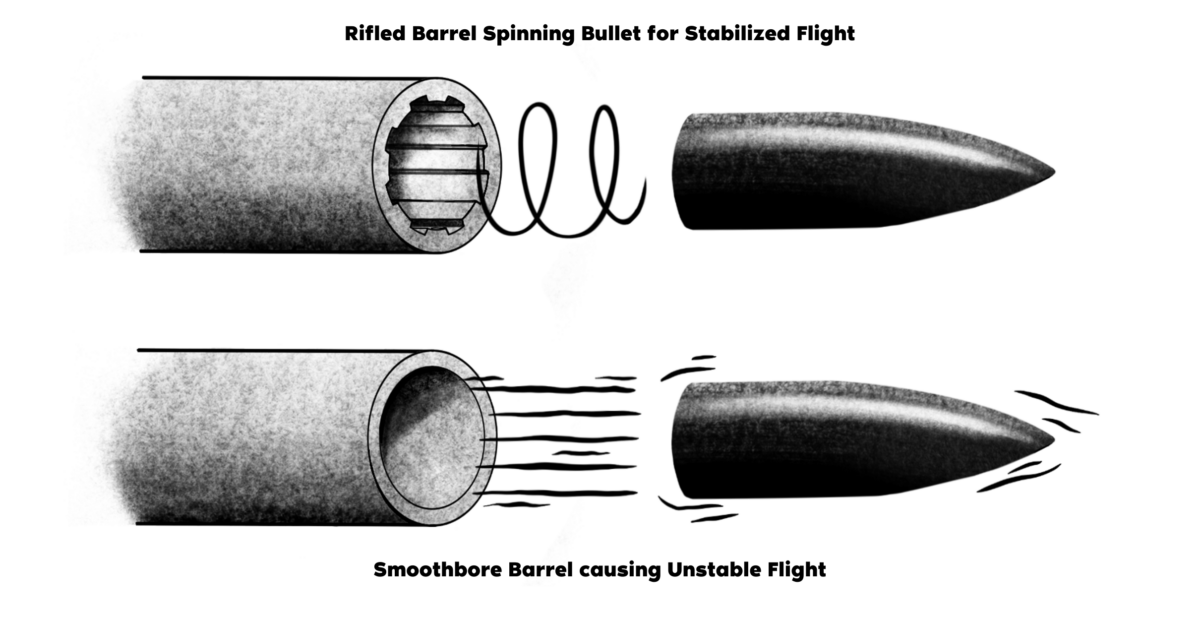

Barrel rifling is the spiral grooves inside the barrel of a firearm that causes the bullet to spin. This spin imparts a gyroscopic stability to the projectile, which in turn improves the bullet’s accuracy.

As mentioned above, we want to stabilize our bullet by spinning it as it leaves our barrel to help it fly as smooth as possible for as long as possible. By doing this, the bullet becomes much more accurate. Think of an NFL quarterback throwing a tight spiral, instead of a floppy ball.

The History of Rifling: When Man Missed a LOT

Before we had rifling inspired barrels in our firearms that we mostly use today, we had the musket. Muskets were a smooth bore, large caliber weapon using ball-shaped ammunition fired at relatively low velocity. Due to this, they were very inaccurate and people generally missed.

Germans changed all of this when August Kotter introduced Rifling at the end of the 14th century. There are a few dates that get thrown around when it comes to the origins of rifling, but it wasn’t until around the nineteenth century that rifling started to become a common addition to the process. The process has been continually improved, to what we have today.

Different Types of Rifling

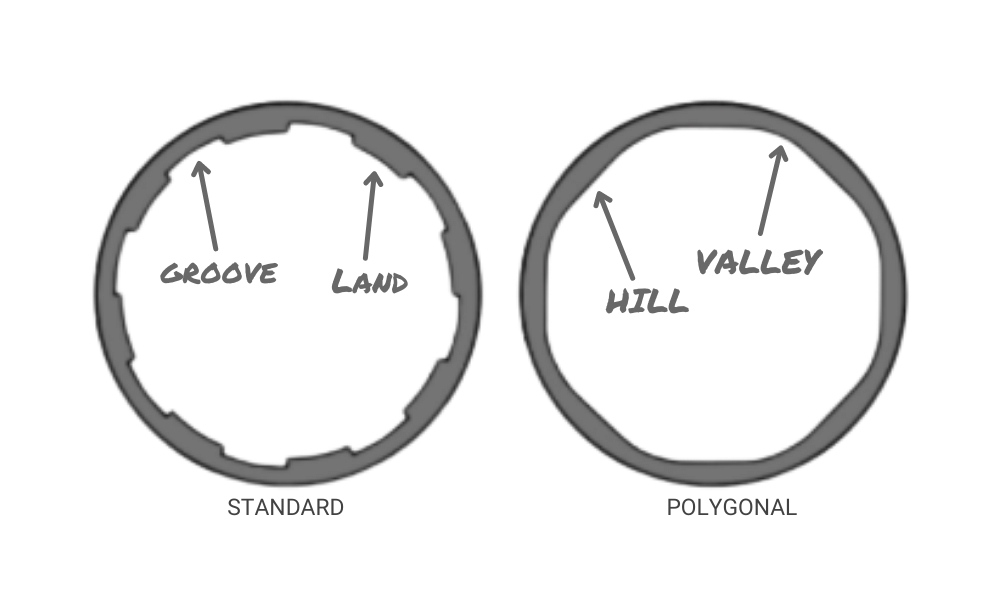

There are two main types of rifling, standard and polygonal.

Standard rifling is a series of alternating high and low spots, called lands and grooves, whereas polygonal rifling has less pronounced hills and valleys and is in the shape of a polygon.

In order for rifling to work, the inside of the barrel needs to be small enough in diameter that the bullet must be deformed slightly in order to pass through the barrel. The fit is so tight that a bullet which is stuck in a barrel can not be pushed out by hand. So, as the bullet pushes forward, the grooves are scraping along the bullet and give it its twist.

Polygonal rifling is usually found in pistol barrels only, and is less common in rifles. Some extremely high-end precision rifles can be found with polygonal bores.

Barrel Twist Rates: Why They’re Important

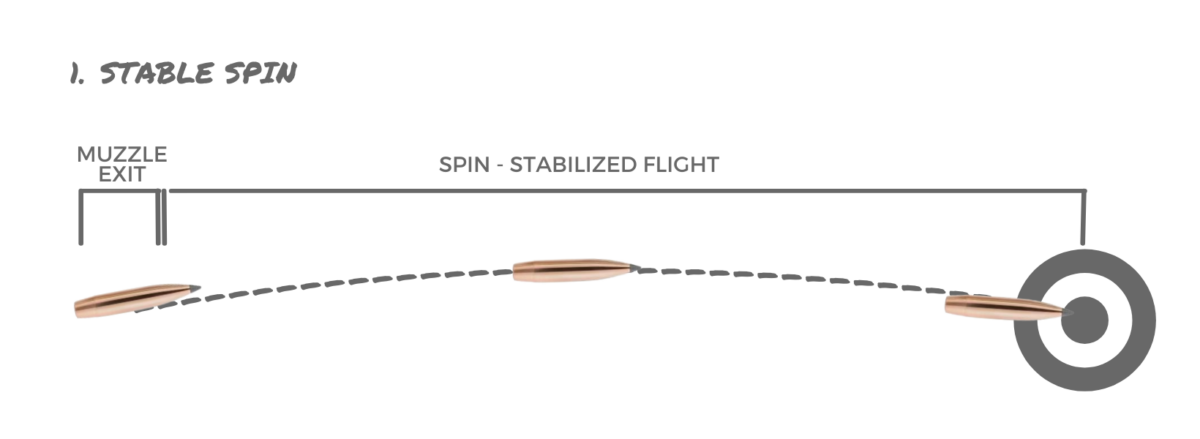

As you learned above, rifling is the act of twisting or spinning the bullet as it travels through the barrel of the firearm. If the amount of spin is just right, then a bullet can travel an optimal amount of distance, in an accurate manner.

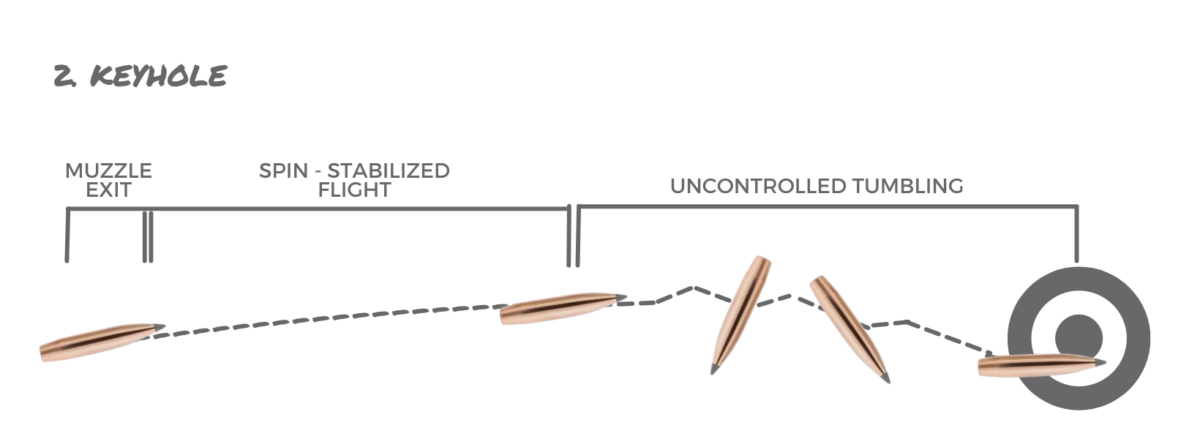

However, if the spin is too great or too little for that particular bullet, the bullet can start to tumble at a certain point in its trajectory, like you see below.

Therefore, it’s very important that the amount of twist created by the barrel’s rifling is adequate for the type of ammo you use with that firearm.

Therefore, an important aspect to know about your barrel is its Twist Rate. This is measured by how many inches a bullet needs to travel in order to make a complete revolution. Different rifles will have different twist rates as faster and slower twists are required to stabilize different weight, size, and speed bullets. You can find the barrel twist rate listed as one of the specifications for the firearm, as well as sometimes stamped on the barrel.

Looking at a firearms specification sheet, you’ll be able to locate the twist rate of that rifle. A twist rate of a barrel is denoted as “1:x” where “x” is the number of inches required for one full revolution of the bullet. Some examples of twist rates can be seen below.

| Tikka T3x TAC A1 | 6.5 Creedmoor | 1:8 |

| Remington 700 | .308 | 1:12 |

| Ruger Precision Rifle | .22LR | 1:16 |

| S&W M&P AR-15 | 5.56 | 1:9 |

Breaking down some ratios from above, 1:8 twist rifling is faster, i.e., tighter twist, than 1:12 rifling because a bullet will make a complete revolution in 8 inches in a 1:8 twist barrel whereas it will take 12 inches for a complete revolution in the 1:12 twist barrel.

As a general rule, heavier bullets in the same cartridge need to be spun faster in order to properly stabilize. For example, 55gr bullets fired from a 223 Remington work well in 1:9 twist barrels but in order to accurately fire a 75gr bullet from a 223 Remington however, a faster 1:8 or 1:7 twist barrel is needed.

Opposed to what you may hear, the twist rate and barrel length have no direct relationship. Twist rate is based on the bullet size, weight, and speed only. Although a barrel’s length can affect a bullet’s speed, it is not necessary for the bullet to exit the barrel after a complete revolution. For example, a 1:12 twist barrel does not need to be 24 inches long so that the bullet has two complete revolutions. Instead, a 1:12 twist barrel can be any length. As a note, most pistol barrels aren’t long enough to allow for even one complete revolution of a bullet.

Key Takeaways

- faster/slower twists required to stabilize different weight/size/speed bullets

- Speed a bullet rotates, measured by number of inches a bullet travels per revolution

- 1:7 is a faster twist rate than 1:10

- Twist rate has no direct relationship to barrel length

Twist Rate Calculations

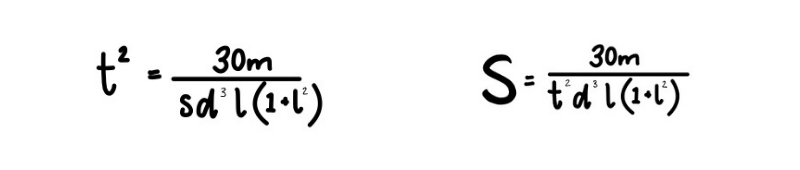

For those of you interested, there are two major calculations that advanced shooters use when working on twist rates: Miller’s Twist Rate/Millers Stability Formula, and Greenhill’s Twist Rate Formula:

Miller’s Twist Rate/Stability Formula

Don Miller derived this mathematical formula to determine the rate of twist to apply to a given bullet to provide optimum stability using a rifled barrel:

- m = bullet mass in grains

- s = gyroscopic stability factor (dimensionless)

- d = bullet diameter in inches

- l = bullet length in calibers

- t = twist rate in calibers per turn

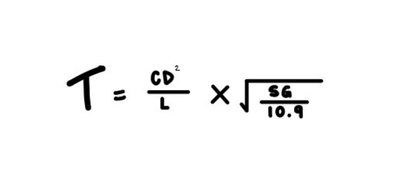

Greenhill’s Twist Rate Formula

Another calculation that’s worth noting is by Sir Alfred George Greenhill. Greenhill was a British mathematician and in 1879 developed a rule of thumb for calculating the optimal twist rate for lead-core bullets.

- C = 150 (use 180 for muzzle velocities higher than 2,800f/s)

- D = bullet’s diameter in inches

- L = bullet’s length in inches

- SG = bullet’s specific gravity (10.9 for lead-core bullets, which cancels out the second half of the equation)

So therefore it can be simplified to;

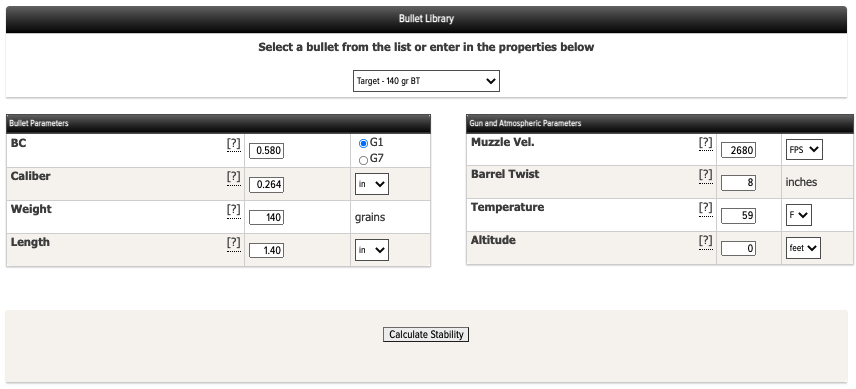

Twist Rate Calculator

There are some other formulas out there for calculating these factors, and at this point I’m just wanting to highlight the fact that these calculations exist. These days we have all of this information at our fingertips and with the punch of a few keys and using some online calculators we can locate the information that we need. Berger Bullets has a great Online Calculator using the Miller Stability Formula as an example of an online calculator, this is much easier than going through the formulas above.

How Rifle Barrels are Made

Rifling in barrels have some similarities in the manufacturing process, although the process generally differs slightly between companies and brands.

The general steps consist of;

- Starting with a steel rod which could be around 12 feet long.

- Cutting the rod down to manageable lengths for processing.

- Drilling through the length of the rod for the bore.

- Rifling applied based on the chosen method by the manufacturer.

- Finish method, cutting barrel threads, cleaning based on the manufacturer.

Even though this is simplified here into 5 steps, there are generally many more complex steps in this process, with many manufactures keeping their trade secrets and their patent designs to themselves. This list is just an overview as we look into the process from making a barrel to applying the rifling.

Different types of Rifling Methods

The creation of the barrel rifling can be accomplished in a number of ways, each with its own advantages and disadvantages.

Cut Rifling – Cut rifling is an older style of manufacturing the rifling. This method uses a cutting action with a hook shaped cutter that creates a groove as it is pulled through the barrel. Each groove was individually cut and required multiple passes of the cutter. This method, although slow, allowed for a lot of adjustability when making changes to the twist rate.

Button Rifling – Button rifling is a method that creates the rifling grooves in the barrel by using a bullet-shaped ‘button’. This can be pulled through the barrel to create the rifling. A great video on this process can be found here, as we get to see the whole process of creating barrels in the Bergara workshop. This process can be very efficient as it only requires a single pass of the button through the rifle.

Broach Rifling – Broach rifling is a rifling cutting process that also can be completed in just a single pass through the barrel. The broach is a metal bar with sets of progressive cutting blades. As the broach is pushed through the barrel, each blade cuts at a slightly deeper depth than the blade before. This is a great option for high volume production. In this method, you would need a new broach for each twist rate that you require.

Cold Hammer Forged – Cold hammer forging is a process where barrels are hammered from all sides in a machine and transfers a mirror image of the rifling which is machined on the surface of a mandrel. In this process, the starting barrel diameter is reduced, and the length increased as the barrel is hammered against the mandrel. A great short clip from Tikka shows this process and describes how all of their barrels go through this method of processing.

ECM – Electrochemical Machining (ECM) is the generic term for a variety of electrochemical processes. ECM is used to machine work pieces through the anodic dissolution of metal. An important thing to note here is that almost any type of metal can be electrochemically machined. You can find a short clip here of this process being used on barrel rifling.

Frequently Asked Questions on Rifling

Do Rifled Barrels wear out?

Certainly, however it usually takes in excess of 10,000 rounds, but if you overheat the barrel with rapid fire it happens a lot sooner.

Does a Shotgun have Rifling?

Generally, shotgun barrels are what’s called “smoothbore,” meaning they are basically metal tubes with a smooth, non-rifled surface inside.

Does barrel length affect rifling / twist rates?

The twist rate has no direct relationship with barrel length.

Final Thoughts

As you can see, barrel rifling is an important part to your accuracy, and further development in long range shooting. By understanding barrel rifling, coupled with the ballistic details of your bullet, will help you correctly match the bullet with the barrel you are wanting to use for your chosen application. If you’re looking at shooting longer distances, then diving into this topic in more depth will be beneficial.

Cheat Sheet: Rifling Summary

That was a lot of information. So, here are the things that you should remember before you leave.

- Barrel Rifling – is the spiral grooves inside the gun barrel, making the bullet spin.

- There are two main rifling types, standard and polygonal.

- There are 5 different rifling methods, cut, button, broach, cold hammer forged and ECM

- Barrel Twist Rate – is the inches a bullet needs to travel in order to make a complete revolution.

- The bullet you want to shoot will determine your required barrel twist rate.

- Faster/Slower twist rates are required to stabilize different weight/size/speed bullets.

- Twist rate matters because a bullet won’t fly straight unless you can spin and stabilize it correctly throughout the flight.

- Rifles and pistols are examples of typical firearms with rifling, whereas shotguns typically have a smoothbore, non-rifled surface.

- Twist Rates have no direct relationship with barrel length.

Recent Posts

February 19, 2026

February 19, 2026

February 17, 2026

February 17, 2026